Description

Here are a few words about our maple syrup from one of the world’s most renowned chefs, Bobby Flay:

“I have admitted that brunch may just be my favorite meal of the week. As a lover of maple syrup, I wanted to introduce you to a new favorite of mine: Mohawk Valley Trading Company’s Pure Maple Syrup from Mohawk Valley and the Adirondacks.

It’s rich, dark sweetness goes perfectly with pancakes and waffles of course but would be great added into oatmeal too. I use maple syrup in my cooking all the time—I add it to a pan sauce for meat and poultry, add balance to a soup or stew as well as vegetables and vinaigrettes. I love when I come across a great quality, local product that I can share with you. And this one is just delicious.”

Maple syrup is a natural sweetener produced by collecting the sap of maple trees, which is boiled and reduced until it becomes thick and syrupy.

Maple syrup from the Mohawk Valley Trading Company is primarily made from sugar maple sap, which is preferred for maple syrup production due to its average sugar content of two percent. Sap from other maple species typically has a lower sugar content, requiring about twice as much to produce the same amount of finished syrup.

Maple syrup grades are mainly distinguished by their color, which corresponds to a specific flavor profile. There are four primary grades: Golden, Amber, Dark, and Very Dark. While all grades are pure maple syrup, the color and resulting flavor intensity differ.

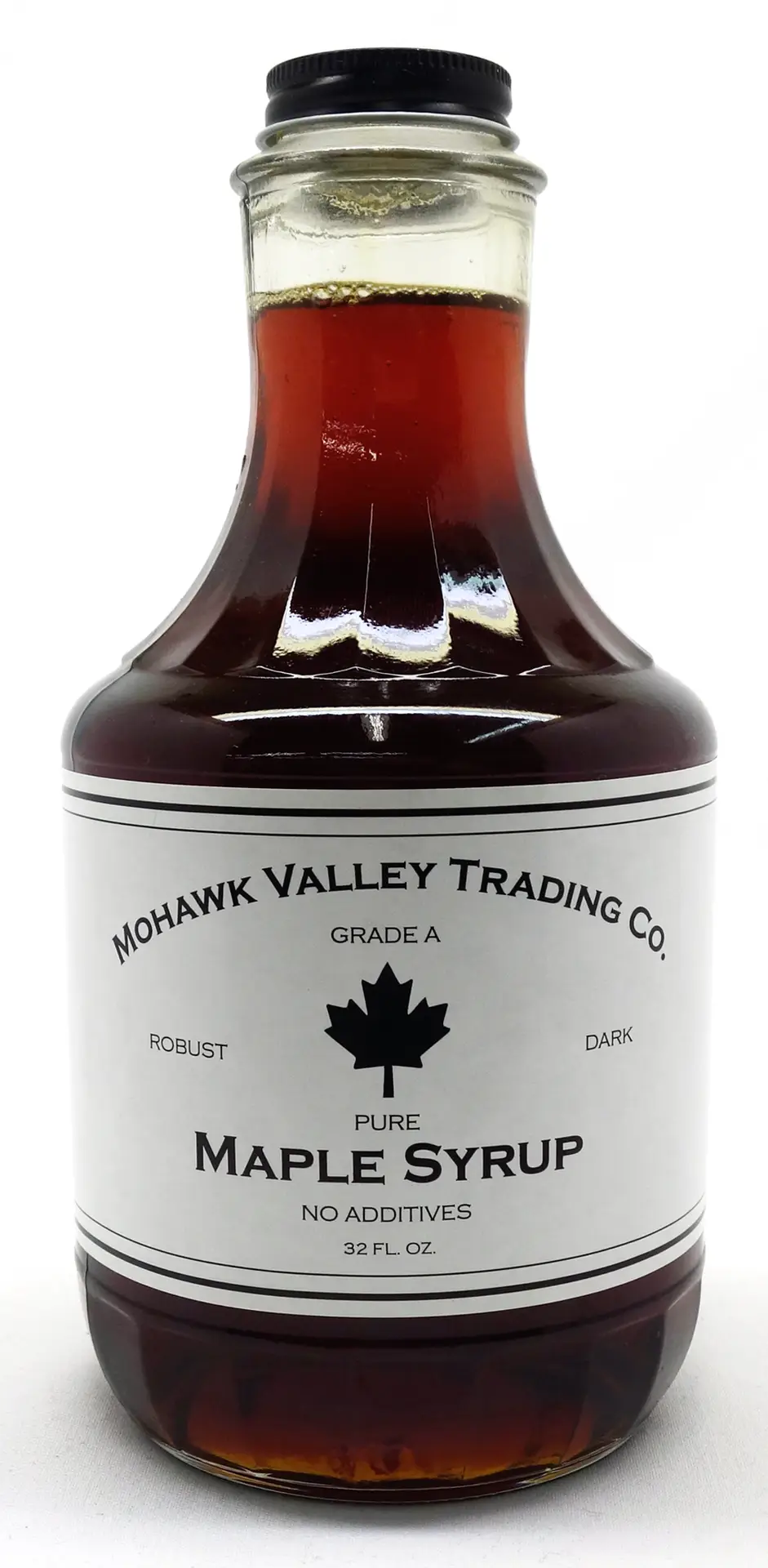

Mohawk Valley Trading Company offers Dark, Robust Maple Syrup, formerly known as Grade B.

Maple syrup is a healthier alternative to regular sugar because it offers potential health benefits due to its antioxidants and minerals, including zinc and manganese. Additionally, it has a lower glycemic index than regular sugar, making it a suitable option for individuals seeking to manage their blood sugar levels. Incorporating maple syrup into your diet can be a delicious and nutritious choice, but as with all sweeteners, moderation is essential.

We do not use pesticides or herbicides in our sugar bushes. Although not labeled or certified organic, maple syrup from the Mohawk Valley Trading Company is as organic as any produced in the USA.

Reviews

There are no reviews yet.